Mechanical Engineering

Labs

Measurement and Metrology Lab

The aim of this lab is to provide the foundation of dimensional measurements such as line or end measurements. After understanding the lab the students shall be able to identify the basic measurement terms & instruments and develop new measurement methods accurately & precisely. All major line & end standard measuring instruments are available in our lab such as Vernier calipers, micrometer, gauge blocks, dial indicators, etc. All surface texture measuring instruments like Profile projector (50X magnification), surface roughness tester are also available. In manufacturing industries for quality assessment of their product, different gauges/instruments are used for accurate measurements.

IC Engine & Automobile Engineering Lab

The aim of this lab is to enable the students to study the various automobile parts in detail with the help of different models. The lab consists of performance test for 4-stroke diesel engine and 4-stroke petrol engine, VCR engine and Morse test. This lab also has models of various automobile parts including fuel injection system, ignition system, multi-point fuel injection system, gearbox and other loose automobile parts.

CAD/CAM Lab

The aim of this lab is to enable the students to model and simulate different machine components by using various software such as C Programming, AUTOCAD, AUTODESK INVENTOR, PRO-E etc., & implement CNC programs for milling and turning operations to manufacture the modelled components and to program the Robotic Arm for performing different applications. CAD/CAM lab is equipped with 65 computers. The modelling software such as Autocad, Autodesk Inventor, Pro-Engineer. CNC Lathe, CNC Milling machine and Articulated Robotic Arm are available in the laboratory to enhance students skills. CAD/CAM Laboratory is a part of B. Tech 7th semester curriculum, which enables the students to become Proficient in drafting and computer skills required in several current industrial standard CAD software to create mechanical designs for product parts, assemblies and system configurations and to apply advanced modelling and computational tools for complex part and shape design and analysis to minimize total cost.

Machine Design Lab

Engineering drawing is the scientific representation of an object, according to certain national and international standards of practice. It can be understood with the knowledge of basic principles of drawing. Machine drawing is the indispensable communicating medium employed in industries to furnish all the information required for the manufacture and assembly of the components of a machine. To make the students understand and interpret drawings of machine components so as to prepare assembly drawings either manually and using standard CAD packages.

Fluid Mechanics Lab

Fluid Mechanics laboratory provides study of fluids and their flows, Pressure variations of compressible fluids when they allowed flowing through convergent divergent nozzles, Calibration of pressure gauges and theoretical demonstration of different laws of fluid mechanics etc. The lab includes various experiments like apparatus for major friction loss, Minor friction loss in pipes, Reynolds experiment, Bernoulli's experiment, Venturi meter, orifice meter, Metacentric height calculation, impulse momentum experiment, Surface tension experiment, Wind tunnel apparatus, V notch experiment and Darcy's apparatus.

Material Testing Lab

The aim of the Materials Science and Engineering laboratory is to enable the students to design a product based on the selection of suitable materials in the best way for the given application, and be in a position to study the structure-properties relation of materials, which is the essence of Materials Science. The material science lab is equipped with the universal testing machine, Hardness testing machine,(Rockwell, Brinell, Vickers ), muffle furnace ,impact testing machine Izode testing machine, Torsion testing machine, Monocular Metallurgical Microscope, Double Disc Metallurgical Polishing Machine, Belt Polisher, Muffle Furnace, Analogue Rockwell Cum Brinell hardness Tester.

Theory of Machines Lab

The aim of this lab is to enable the students to acquire the desired knowledge of various types of mechanisms used in a variety of machines. Also this lab is very helpful for removing the complicacy of the subject through the working models, corresponding charts and the testing apparatus which are an integral part of the lab. This lab consists of 11 experiments viz. motorized gyroscope, universal governor apparatus, static and dynamic balancing cam analysis, whirling of shaft, epicyclic gear train apparatus, models of simple mechanism universal vibration apparatus. Students will understand the different types of mechanisms, their application in different machines and their usefulness. From this lab, they will be able to perform these experiments.

Manufacturing Processes Lab

This lab consists of experiments regarding machine shop and welding shop. In machine shop experiments are performed on lathe, capstan lathe, shaper, slotter & milling, drilling, and grinding machine. In welding shop different types of welding joints such as lap, butt, corner, T- joints of same work piece are fabricated using different welding techniques such as Gas, Arc, TIG, MIG, seam, and spot welding. This lab enables the students to get thorough knowledge of different metal cutting processes and fabrication processes used in industry. This lab also consists of experiments regarding foundry, smithy, carpentry, sheet metal shop. In foundry shop experiments are performed regarding mold making, casting and sand sieve testing. In smithy shop both hand forging and power forging (with help of pneumatic hammer) operations are performed. Different types of pattern with pattern allowances are made in the carpentry shop. In sheet metal shop punching, piercing and blanking operations are performed with the help of hand press. Apart from this, wire drawing and pipe bending operations are also demonstrated. This lab enables the students to get a thorough knowledge of different primary manufacturing processes such as casting and forming processes used in industry.

Applied Thermodynamics Lab

Aim of this lab is to enable the students to study different aspects of thermodynamics with the help of different models and equipment and to apply concepts of basic thermodynamics in enhancing their ability to design different thermal machines. The lab consists of Air compressor apparatus, Models for steam boiler (water tube and fire tube), Diesel engine, Petrol engine, Steam turbine, Gas turbine and Steam engine. Applied thermodynamics lab finds its application in all types of industries such as automotive, aerospace, power plants, petrochemical , energy conversion, environmental control industries, etc.

Mechanical Workshop Lab

The aim of the central workshop is to impart practical knowledge and on hand practical skills to the students necessitating to be a competent engineer. The main purpose of an engineering workshop is to provide the basic working knowledge of the different types of production operations used in manufacturing industries. Further the associated knowledge of central workshop equips the students with basic knowledge and applications of various types of tools, equipment, machinery and techniques used in manufacturing to provide different shapes to the raw material into useful products and components. The Workshop is equipped with the state-of-the-art like Lathe Machines, ,Milling Machine, Shaper Machine, Slotter Machine, Drilling machines, Gas welding equipment, Arc Welding Machines, MIG Welding Machine, TIG Welding Machines, Spot and Seam Welding Machine, Surface Grinding Machine, Bench Grinder, Hand Shearing Machines, Power Hacksaw, Hydraulic Hacksaw, Open Hearth Furnaces, Wood working lathe, Bending Machine etc. Central workshop lab finds its application in all types of industries such as metal cutting, fabrication, Foundry, Forging, etc. The importance of the lab is also recognized in repair and maintenance work used in all types of industries.

Engineering Graphics & Design Lab

The aim of the Computer Aided Engineering Graphics lab is to increase the visualization capability in engineering applications. Students also learn Engineering Drawing and AutoCAD for better future perspective. We have a drawing hall with 60 drawing tables and a dedicated computer lab with 30 high configuration computers loaded with designing and drafting software for Computer Aided Engineering Graphics (CAEG) Lab. Both labs are equipped with LCD Projectors for better way of teaching. Engineering drawing is essential for communicating ideas in industry and engineering. To make the drawings easier to understand, people use familiar symbols, perspectives, units of measurement, notation systems, visual styles, and page layout. Together, such conventions constitute a visual language, and help to ensure that the drawing is unambiguous and relatively easy to understand.

Fluid Machinery Lab

The purpose if this laboratory is to reinforce and enhance understanding of the fundamentals of Fluid Machinery. The laboratory experiments are designed to demonstrate the applications of fluid mechanics principles and provide a better understanding of theoretical approach. The main aim is to understand fundamental concepts and significance of various experiments like Impact of Jet, Pelton Turbine, Francis Turbine, Kaplan Turbine, Hydraulic Ram, Centrifugal Pump and Reciprocating Pump.

Heat & Mass Transfer Lab

Heat & Mass Transfer Laboratory caters to the needs of B.Tech. 3rd year Mechanical Engineering. There are 10 experimental setups available in the laboratory. They are- 1. Natural convection apparatus 2. Force convection apparatus 3. Stephan-Boltzmann apparatus 4. Composite wall apparatus 5. Specific heat apparatus 6. Heat Pipe Demonstration 7. Parallel flow/Counter flow heat exchanger test rig 8. Plate fin heat exchanger test rig 9. Critical radius apparatus 10. Thermal conductivity apparatus These experiments help the students to understand all the 3 modes of heat transfer, namely conduction, convection and radiation practically. These experiments also pave way for inculcating certain innovative skills in the students making them to use the above experimental setups as starting point to take up higher level experimental studies in Heat Transfer.

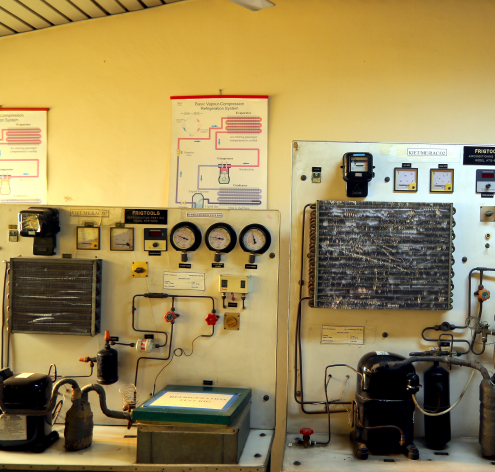

Refrigeration & Air-Conditioning Lab

Refrigeration is a process to maintain Temperature of the system lower than the Temperature of surroundings whereas air conditioning is the conditioning of air according to the requirement. Air conditioning relates to control of temperature, humidity, wind velocity and purification of air. In RAC lab students get the information about the working of refrigeration and Air conditioning systems. In this lab students study and perform eight experiments in two groups. In the first group of experiments students get the information of expansion devices, evaporators, main component of air conditioning system and working of window air conditioner. In the second group of experiments students will study air washer and calculate the different performance parameters of refrigeration test rig, air conditioning test rig. At least one industrial visit for students to any cold storage plant or central air conditioning plant has been made a part of our RAC lab curriculum.